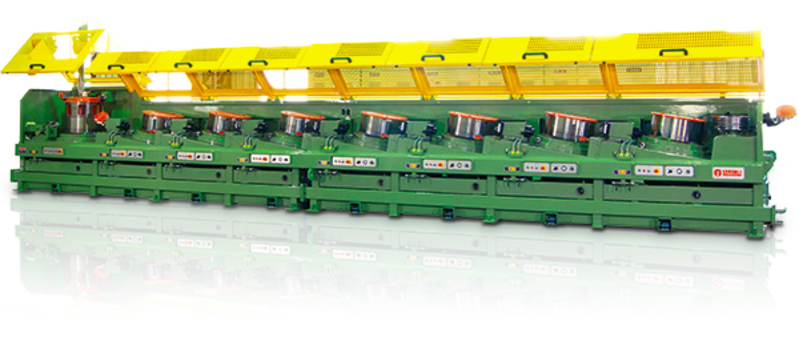

straight Line Continuous Wire Drawing Machine

●SCWD-900

●SCWD-760

●SCWD-700

●SCWD-600

●SCWD-400

●SCWD-300

1. Wear-Resistant Drawing Capstan

The wire drawing zone through tungsten carbide coating and polishing and surface hardness is up to 70 HRC.

2. Dancer Type System

The wire goes through the dance then passes the guide roller located above the capstan. This ensures wire entering into the die without any shaking problem.

3.Tuner/Sensor Arm Type System

The wire passes the Tuner/Sensor Arm then into the next drawing die directly. Easy to operate the machine.

4.Patented Gearbox and Cooling System

Very high efficiency Cheng I patented gearbox (>95% on the entire speed range). Cheng I patented cooling capstans, with an extremely high cooling capacity.

5.Die Box and Roller Cassette Exchangeable Design

Any type & brand of Roller Cassette or Die Box can be installed in drawing machine.

6.Advanced HMI Panel (Touch Screen and User-Friendly Operating Interface)

The machine is equipped with an advanced HMI panel. The software is designed by highly experienced control engineer. Easy to operate and monitor the machine.

7.Distributed I/O Design

Installing the Siemens ProFiBus Net system; this includes distributor I/O from machine side to save wire control cost and lift EMC interrupt resistance and enhance quick wiring.

OPTIONAL DEVICES :

1. Rotary Die Device.

2. Wire Diameter Measuring Device.

3. Constant Measuring Device.

4. Wire collection Type : Coiler Type or Spooler Type.

5. Patten Layer System.

6. Dies or Cassette System.

7. Pressure Dies Device.

| MODEL | Inlet Wire Dia. (mm) | Drum Dia. (mm) |

| SCWD-300 | 2.4~2.0 | 300 |

| SCWD-400 | 4.5~3.0 | 400 |

| SCWD-600 | 6.5~5.5 | 600 |

| SCWD-700 | 8.0~6.5 | 700 |

| SCWD-760 | 10.0~8.0 | 760 |

| SCWD-900 | 13.0~10.0 | 900 |